Key Technology (KeyTech) explores the intelligent driving solution with vision-safety technology under the ADASPLUS brand since 2015. Integrated artificial intelligence algorithms, deep learning, and facial recognition make our ADAS system the top player in China with a market share of over 90% of SDK for our Dash Cam and Rearview Mirror. Our ADAS system deployed more than 10 million vehicles and devices. With more than 90 experienced and professional engineers enable KeyTech has the ability to strategically cooperate with Tier-one suppliers and Automakers as well as welcome all private-label projects both for aftermarket and those pre-installed automobile markets.

Our R&D team has professional experience of ADAS over 10 years, core team-members focus on deep-learning and facial recognition and Artificial Intelligence for years, which ensures our algorithms in a high level in the industry. Our technology has fallen into Forwarding Advanced Driver Assistance System, Rear Advanced Driver Assistance System, Driver Monitoring System, Blind-Spot Detection, Facial recognition, KeyTech OS, with a Big Data and Cloud Platform.

KeyTech is a young but ambitious and a leading enterprise solution, after six years of development, KeyTech is well-known in China and a growing business with first-tier suppliers supported in Japan, Korea and now expanding to North America and Europe.

Launched more innovative Pre-installed products for Tier 1 suppliers.

Signed more contracts with Japanese and Korean automakers through Tier 1 suppliers.

Launched more innovative fleet management hardware.

Achieved more professional awards.

Gained Round A+ venture capital over 100 Mllion RMB.

Over 10 Million Users.

Top 1 ADAS SDK supplier in China.

With market-share over 90% in Smart-dash Cam and Intelligent Reawview Mirror.

Fleets Management platform online, offer full-stack services.

Car-sharing Solutions to Capitial-auto Car-sharing company.

Developed ADAS SDK for rearview mirror and occupied China market rapidly.

Founded Taiwan Pre-installed team Successfully signed a contract with Tier1 supplier.

Founded, Developed ADAS SDK for 70mai(Xiaomisubbranch), Dash Cam, to enter the automotive aftermarket business.

Preparation of pre-installed market.

Preparation. Core R&D members have more than 10+ years of experience both in the ADAS and Artificial Intelligence field.

Mechanical impact table

Temperature shock test chamber

Vibration table

Ultra low temperature humidity control box

SMT Workshop

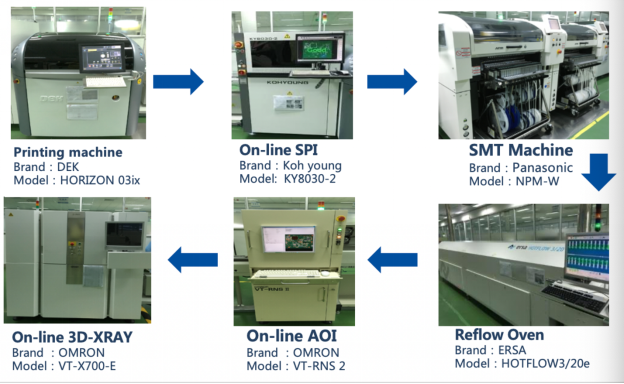

7 High-precision production lines. Machine Accuracy reaches 01005.

Machines in SMT lines

PCB Workshop

Selective Wave Soldering Welding Robots

6 production lines and 4 different styles of welding process which would meet different demands from our clients.

Assembling Workshop

8 FAT production dust-proof lines.

POKA-YOKE assembling line and testing line.

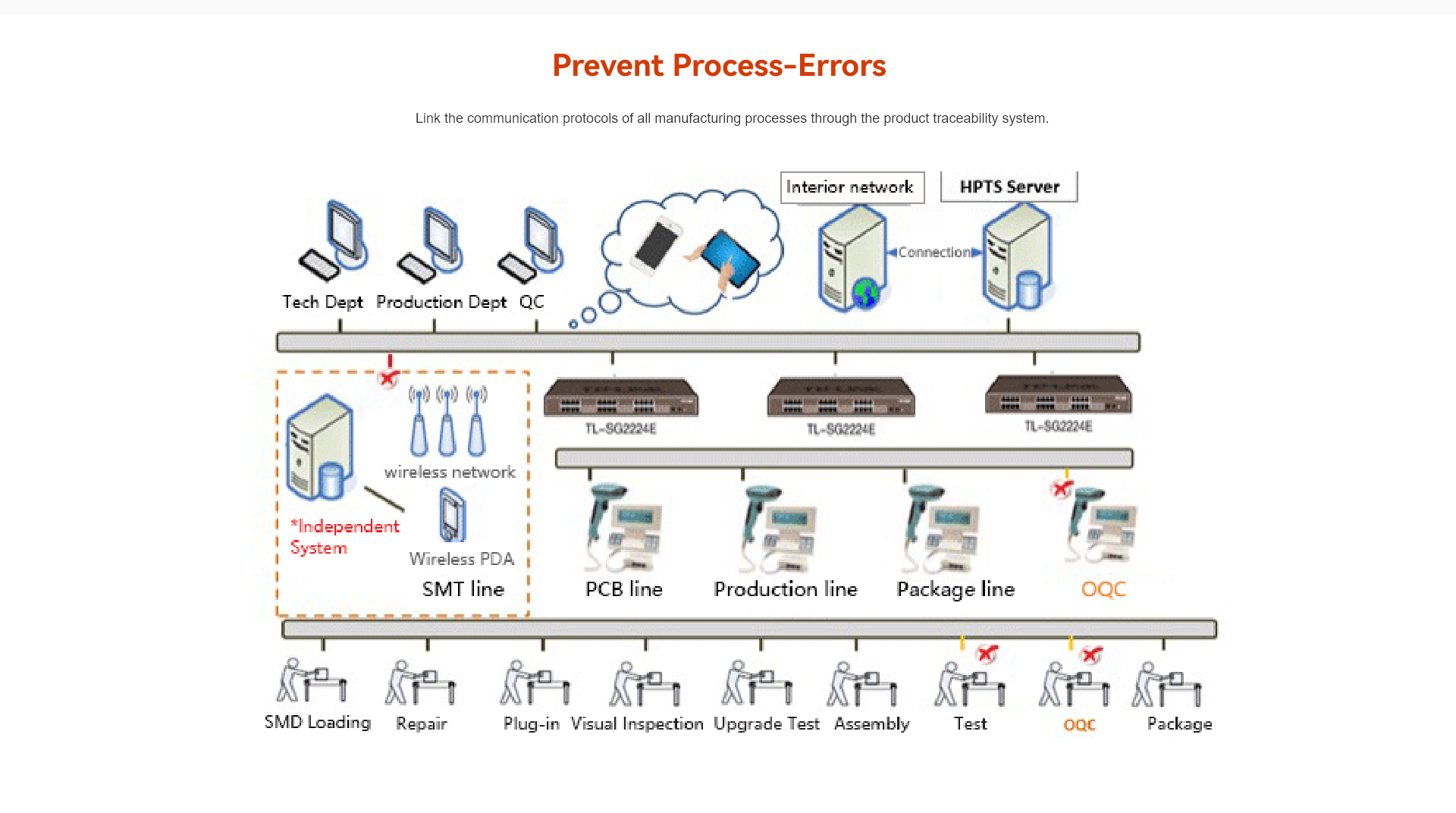

Workstation Error Proofing

Visualize the entire process through sensors and machine-based monitoring technology.

Link the communication protocols of all manufacturing processes through the product traceability system

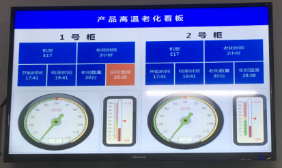

Product Reliability Processing

Early GP12 Management High and Low Temperature Experiment

General High Temperature Combustion Test Visually Related Product Traceability System

OUR SHENZHEN WORKSHOP

Aging Room: 500 square meters

1. Equipment accuracy: 55+/ -5 ℃, equipped with a temperature zone control system.

2. The separated computer room has an independent power supply, equipped with an automatic conveyor belt, buffer streamline, and strong product compatibility.

Small Products Assembling lines

8-40 assembling lines which including, preparation, welding, assembling, testing, online checking and packing.

Big Product Assembling line

Big production with aging-spot on the top with separated power supply.

Automatically transfers the products to the next spot to finish the process, Which includes preparation, welding, assembling, testing, higher temperature aging, online checking, and packing.

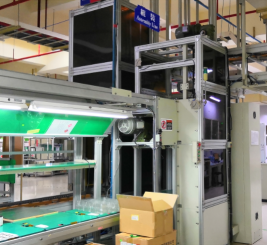

U-Assembling line

standard assembling lines besides with U-Assembling line, Lower lines automatically send products to the higher level, which whole procedures including preparation, welding, assembling, testing, aging, online checking, and packing.

Tel: +86-10-53511855

Domestic: bd@adasplus.com

Oversea: sales@adasplus.com

Media: media@adasplus.com

版权所有2003-2021开易(北京) 科技有限公司保留一切权利